SAFE OPERATION

Delivered high quality and high reliability since 2005

THE PRODUCT

The TWO is a robust, durable, and accurate instrument for precise and efficient pavement friction measurements. The patented design works just as well in -30 degrees snow and ice conditions as in +50 degrees tropical environment.

The TWO is made of stainless steel and high-quality Aluminum it will not rust or corrode. There is either no hydraulics that may freeze or leak or get worn.

The TWO can be mounted directly on a vehicle or pre-installed on a special trailer. Both installations are available with optional self-wetting system required for pavement maintenance purposes.

There are solutions for mounting in line with left or right vehicle wheel track – or in between.

The software is installed in a laptop located at the driver seat. It will handle measurement, display and store data. The program ensures easy operations, collects results and enables reporting of details immediately after the measurements are performed.

HOW IT WORKS

The unit is raised and lowered by an electric actuator that is controlled by the TWO software. In upper position the TWO is free in the air and not in contact with the surface below. This is the normal position when moving between sites.

When lowered the device is pushed to the ground at a preset force by the electric actuator. The down force is measured and automatically controlled by the software.

The 2 wheels are connected mechanically by a chain. Front wheel has about twice the down force as the rear wheel. That makes the front wheel the driving wheel and is running at the same speed as the vehicle.

The rear wheel is the measuring wheel and driven by the driving wheel via the chain, but is geared so it is rotating 17.8% slower than the driving wheel.

Friction level is recorded at 100Hz and is calculated by dividing measuring wheel down force (Fd) by the measuring wheel braking force (Fb); Friction coefficient = µ =Fd/Fb.

Details and solutions

Friction measurements made easy! We offer the following options.

TWO trailer friction tester

Designed for easy towing with any vehicle. Trailer shown without self wetting system. Lifting and lowering as well as starting and stopping is done from the drivers seat

TWO trailer mounting

Easily attached to all vehicles equiped with standard trailer hook. This offers a flexibility to use several different vehicles for measuring tasks.

TWO center mounted

Centermounted TWO using a standard 2” square trailer hitch. This is a very common attachment and a perfect solution for airports. We deliver the friction meter pre-assembled for this type of attachment with flexible height adjustment

TWO in lifted position

Ready for transport between locations. The device is easy to attache and remove after use.

Summer measurements

Nozzle for self-watering of the rear meassuring wheel to record reliable measurements on dry surfaces. Designed to leave 0,1mm -1,0mm waterfilm in front of the measurement wheel. The amount of water is automatically adjusted according to the speed of the measuring wheel

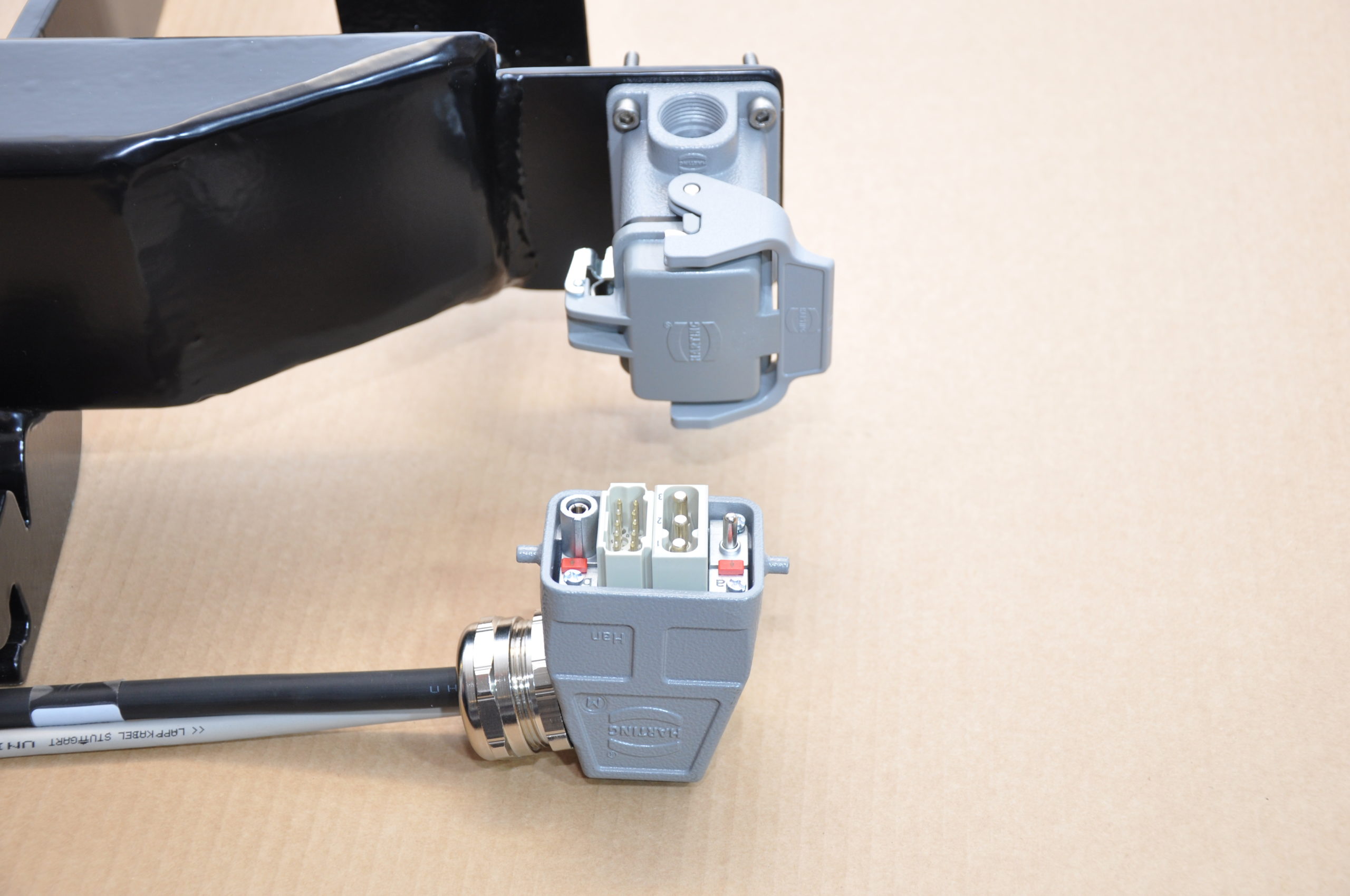

Mountingbracket

The supplied mounting bracket must be fitted to the vehicle’s load-bearing structure on vehicles equiped with standard tow bar. This offers both rear left-hand or right-hand side mounting of the friction meter.

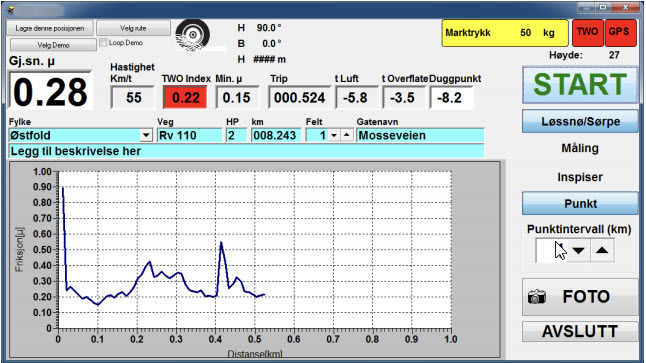

The software beauty

Software

The friction meter comes complete with special designed software and will provide you with all informations needed for measurements. You will be able to govern the whole process via the laptop from your drivers seat.

The TWO software is prepared for any language.

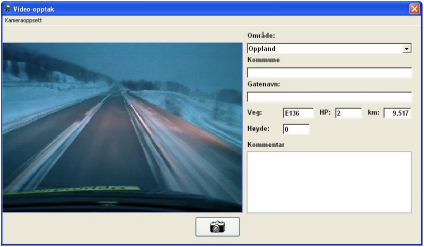

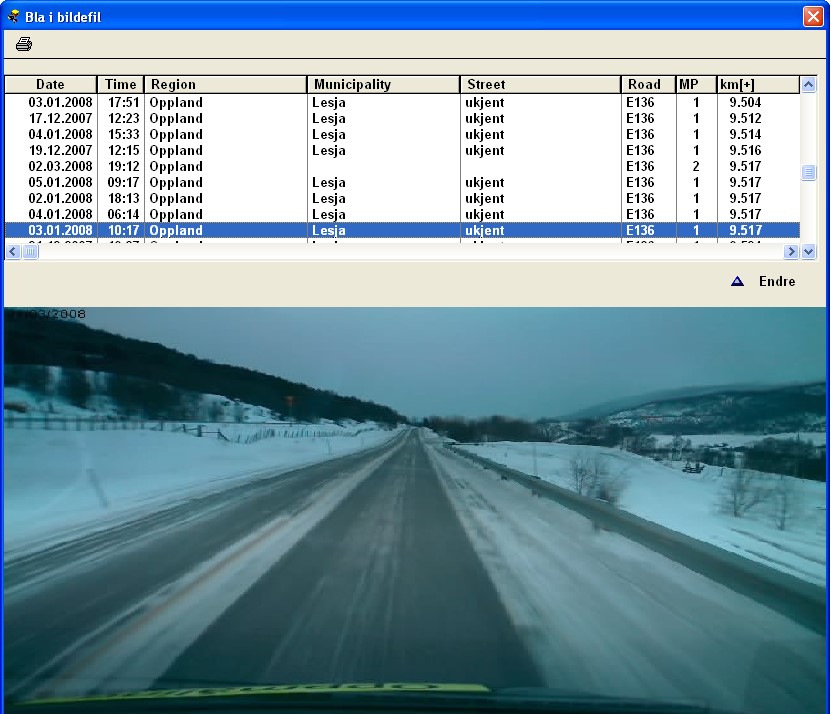

GPS/Photo

A GPS receiver is used to indicate the position of the measurements. A camera is used to supplementary document the condition of the road or airports. An air and infrared camera temperaturunit is also available. 3 sensors covers air, track temperatures and humidity. Information needed for a qualified assessment of the need of actions to be taken

Monitoring / reporting

The program ensures easy operation, collects and stores measurement data. You will be able to report and share informations immidiatly after the meassurements are performed. The values belove friction requirements will emerge in red color and values above requirements for friction will be colored green.